This product is 'Made to Order' and is subject to a manufacturing lead time of at least 3-4 weeks and is non-returnable.

DESCRIPTION

Replacing the catalytic converter on your VR6?

Our SLC VR6 high flow cat is the performance fit! The stock catalytic converter on most VR6 vehicles is a lengthy 600 cell catalyst. While failures are infrequent, replacement with a high-flow cat yields better exhaust flow & mild HP gains. Our VR6 high flow cat uses a 400 cell metal cat in a spun stainless steel body. A CNC machined flange & TIG welded construction result in a perfect fit every time. Auto parts store replacement cats are guaranteed to 'pretty much' fit & basically 'work'. Why settle?

Our SLC VR6 high flow cat is available reduced to fit the stock sleeve clamp, or 2.5" through to fit 2.5" cat-backs. A fresh OEM gasket & replacement hardware is included with every pipe. Two oxygen sensor bungs are welded in and a plug is included for the extra. OBD1 cars use the pre-cat bung. OBD2 cars use the post-cat bung. Though based on the mk3 VR6 cat, our high flow cat fits a wide range of VWs. Check out the list below to see if this cat fits your car.

This High Flow Cat Fits:

- 1992-1995 VW Corrado SLC VR6

Construction

- CNC mandrel bent 304 stainless steel tubing

- CNC waterjet cut 304 stainless steel flange

- 409 stainless steel 400/cell metal catalytic converter

- TIG welded construction

- OEM multi-layer gasket

- Stainless steel hardware & copper coated locking nuts

Fitment

- Professional installation is highly recommended.

- Fits exactly like the stock cat. No cutting or custom fitment required

- Oxygen sensor bung location suits every vehicle without modification of heatshields or sensor wiring. OBD1 & OBD2? Don't worry, one model fits all

- Includes stainless steel hardware and OEM gasket

- Available reduced to fit stock band clamp or 2.5" through

- Replacement sleeve clamps available

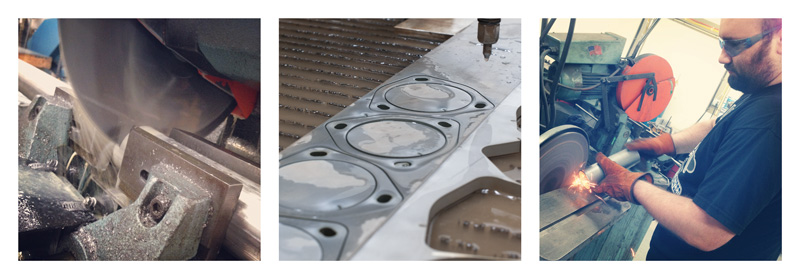

Every 42 Draft Designs exhaust system is scratch-built from straight tube and flat steel. Our team of professional metal fabricators cut, bend and form raw materials with precision. Piping is mandrel bent in-house using our Baleigh CNC mandrel bender. Flanges and brackets to fit each system are cut on our OMAX waterjet. Additional forming takes place using our Huth end forming equipment and our Dake 100 ton press. We use ONLY the finest North American made materials proven to stand the test of time.

Every component of each individual exhaust system is treated to a precision assembly and test fixture. These fixtures allow our fabrication staff to accurately build, weld, and test each assembly. Nothing's worse than a product that doesn't fit; so we work smart to ensure every system fits like the first.

After assembly each exhaust system is TIG welded by our team of professional welders. Our welders take their time, preparing, welding and inspecting each joint with care. From raw material to final welding we never rush, cut corners, or take shortcuts.

Throughout our exhaust systems we use the highest quality American made materials. Our piping is shipped directly from the mill, wrapped in a crate to prevent dents and scratches. We use heavy gauge aluminized steel and stainless steel tubing designed specifically for mandrel bending. Flanges, brackets and hangers are cut from cold roll steel. (Hot roll steel is more economical, but we're willing to pay more for clean, flat steel free of scale and glaze.)

In the end, our attention to detail and demanding material choices increase the retail price of our exhaust systems. When compared side-by-side with the competition our products always stand out. We use better materials that are proven to stand the test of time. We put more time and more care into each of our exhaust systems than anyone in the business. Quality, performance, fitment accuracy, and your satisfaction are standard features of all 42 Draft Designs exhaust systems.

Legality

- This product is equipped with a 48 state legal Magnaflow catalytic converter.

- Emissions laws vary by state. Check local and federal laws before modifying your exhaust system.

- Emissions compliance is the sole responsibility of the vehicle owner.

- This modification may cause 'catalyst below efficiency' fault code and Check Engine Light (CEL) / Malfunction Indicator Light (MIL) to illuminate.

Fitment Details - 2.5" Through

2.5" high-flow cats fit exactly like the original but lack the reduction to stock band clamp size. This allows for a straight-through fitment when using 2.5" exhaust. Our 2.5" through high-flow cat terminates at the center of the stock band clamp. Many 2.5" cat-back exhaust systems for the SLC VR6 have a built in reduction to the stock band clamp size. In this case, the cat-back exhaust system will need to be modified. The reduction will need to be removed, a 2.5" section of pipe added and a 2.5" band clamp added. Many cat-back exhaust systems begin at the center of the stock band clamp as 2.5". In this case no modification is required and a band clamp should be used. Due to the variances in aftermarket cat-back designs we cannot guarantee a 100% bolt-on 2.5" through high-flow cat for any or all aftermarket exhaust systems.