CSF 2020+ Audi C8 RS6/RS7 High-Performance Intercooler | 8194

Following our debut of our world exclusive All-Aluminum Radiator for the B8 S4/S5, we are excited to announce another world’s first release: CSF’s highly anticipated High-Performance Intercooler System for the new C8 RS6 and RS7.

We’ve teamed up with leading VAG specialists from Southern California, Pacific German, to bring this critical intercooler system to market, unlocking the full potential and increasing power goals of the new C8 platform.

CSF has again teamed up with strategic manufacturing partners, PWR, to bring Formula-1 performance to the aftermarket.

Design & Engineering

| OEM | CSF by PWR | |

|---|---|---|

| # Of Tubes | 22 | 45 |

| Tube Height | 7mm | 3mm Rolled Tube |

| Fin Height | 7mm | 4.85mm |

| Design | Crimped w/ Gasket Cast Endtanks |

100% TIG Welded CNC Billet End Tanks |

Core Technology

The most important feature of the CSF by PWR RS6/RS7 Intercooler System is the Formula-1 grade intercooler core. CSF’s strategic relationship with PWR has allowed the inclusion of this core, which is unlike any other available in the performance aftermarket.

- 3mm tall, rolled tubes with turbulated inner fins maximize the dissipation of heat from the charge air flowing through the pressure side of the intercooler core

- The 4.85mm tall multi-louvered fin is the most efficient fin in the high-performance industry, with performance similar to PWR’s Formula-1 grade race intercooler cores

Proven on CSF’s similar air-to-air twin intercooler systems, for both Porsche 992 Turbo/S and GT2RS, these cores eliminate heat soak and lower Intake Air Temperatures (IATs) to allow maximum performance of the vehicle for an extended period of demanding driving conditions.

As evident from the dyno testing (see graphs below), one of the biggest advantages of CSF’s new C8 RS6/RS7 Intercooler System is the recovery speed in dissipating heat from the turbocharger system.

With the OEM intercoolers, the new C8 platform starts to exhibit heat soak and run-away increases in IATs, which then triggers the ECU system to pull timing out of the engine and subsequently lowers performance.

CNC Machined Billet End Tanks

As with our other products produced through our PWR partnership, our new RS6/RS7 Intercoolers feature 100% TIG-welded machined billet aluminum end tanks vs. the OEM crimped cast aluminum end tanks. This feature is not only aesthetically pleasing, but is also stronger for longevity and durability on high-performance vehicles. The CNC machined billet end tanks are ready to withstand increased boost pressures from bolt-on modifications, higher performance tunes, as well as upgraded turbochargers.

With the enthusiasm that RS6/RS7 customers have for their vehicles, the platform is already pushing past 800 WHP (on its way to 4-digit power levels) and the CSF intercoolers are one of the critical components in reaching these power goals.

Dyno Testing

In-depth engineering processes and testing alongside leading VAG tuning/supercharger specialist, VF Engineering, and Pacific German allowed us to make this high-level vehicle’s components just as refined as the vehicle itself.

"WE TESTED THE CSF INTERCOOLER UPGRADE WITH A TUNED RS6 AT VF ENGINEERING USING THEIR IN-HOUSE MUSTANG FOUR WHEEL DYNO. IN DOING SO, WE WERE ABLE TO SEE REAL WORLD ABUSE ON THE STOCK INTERCOOLERS BY STARTING WITH A TUNED RS6, PERFORMING SEVERAL BACK-TO-BACK DYNO PULLS WITH 50 SECONDS COOL DOWN IN BETWEEN PULLS (1-MINUTE INTERVALS WITH 10 SECOND PULLS). WE THEN FLASHED THE CAR TO THE OEM TUNE AND RAN THE SAME BACK-TO-BACK PULLS ON THE DYNO. ONCE WE HAD THE DATA COLLECTED FOR THE OEM INTERCOOLERS, WE REMOVED THE BUMPER COVER AND SWAPPED OUT THE FACTORY UNITS FOR THE UPGRADED CSF INTERCOOLERS, AND IMMEDIATELY TESTED THE CAR AGAIN USING THE SAME METHODOLOGY AND CONTROLLED TESTING, WITH A OEM TUNE AND THEN FLASHING ONTO THE VEHICLE, THE VF ENGINEERING STAGE-2 PERFORMANCE TUNE.

THE DYNO CELL WAS 8°F WARMER IN THE AFTERNOON, DURING THE TESTING WITH THE CSF INTERCOOLERS INSTALLED, THAN THE MORNING TESTS OF THE OEM INTERCOOLERS. HOWEVER, WE SAW A HUGE IMPROVEMENT DESPITE THE WARMER CONDITIONS. WITH THE OEM INTERCOOLERS, THE TEMPERATURE ROSE 20°F ON AVERAGE EVERY PULL ON THE DYNO. WITH THE CSF INTERCOOLERS, THE TEMPERATURE DROPPED 4°F ON AVERAGE EVERY PULL ON THE DYNO. SOME PULLS AT PEAK TEMPERATURES WERE 30°F COOLER WITH THE UPGRADED CSF INTERCOOLERS COMPARED TO THE OEM UNITS. THE OEM INTERCOOLERS BEGAN TO SHOW SIGNS OF HEAT SOAK AROUND THE 3RD PULL, HOWEVER WITH THE CSF INTERCOOLERS RECOVERY WAS NEARLY INSTANT AND SHOWED MINIMAL SIGNS OF HEAT SOAK EVEN AFTER THE 5TH PULL."

TYLER SETTERSTROM, LEAD TECHNICIAN AT PACIFIC GERMAN

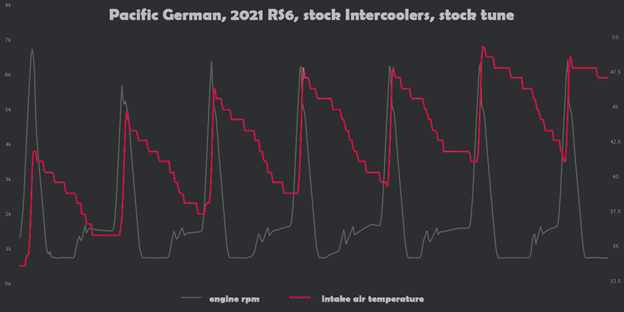

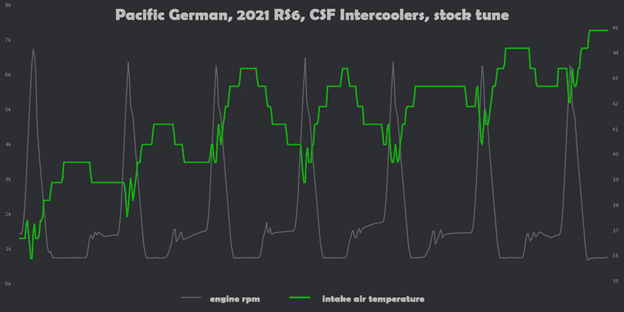

These two graphs show the comparison of OEM (Left) and CSF Intercoolers (Right) with a factory OEM engine tune on an Audi C8 RS6. As you can see from the graphs above, the OEM intercoolers start to exhibit heat soak early on in the testing, already starting to affect performance on the 3rd dyno pull. IATs go up with engine speed. With the CSF intercoolers, the temperature drops as engine speed increases, and recovery between dyno pulls is very quick.

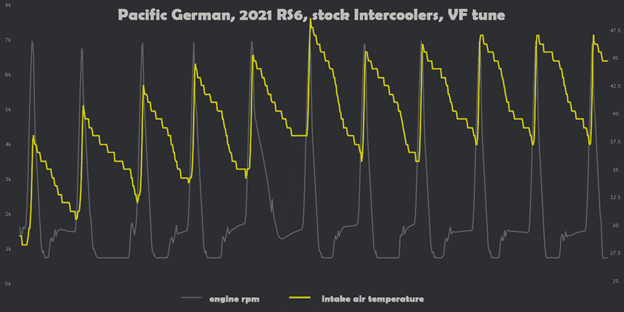

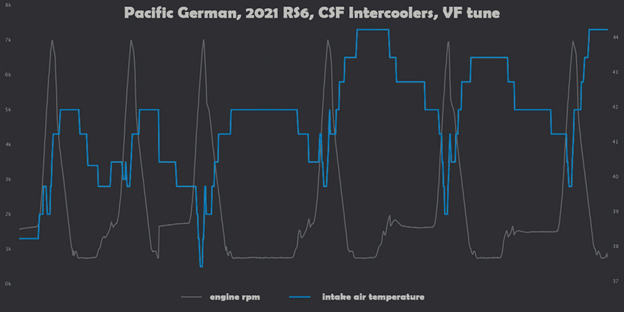

The second set of graphs compares the OEM (Left) and CSF Intercoolers (Right) with VF Engineering Stage-2 engine performance software. In these graphs, like the previous ones as well, the OEM intercoolers allow for heat to rise as engine speed increases. With the CSF Intercoolers, the intake air temperatures drop as engine speed increases. IATs are much more stable with the upgraded CSF units compared to the OEM intercoolers.

Maximum performance, increased recovery speed, stronger design and more power – another industry-leading design, exclusively by CSF.

CSF High-Performance Intercooler System Features (CSF #8194 / #8194B):

- Sold as a set (Pair of Left & Right)

- Formula-1 Performance Grade Core by PWR (2-Row Core Featuring Rolled Tubes w/ Inner Fins)

- CNC Machined Billet End Tanks

- 100% TIG Welded vs. OEM Style Gasket and Crimped End Tanks for Maximum Durability

- OEM Style Inlet/Outlet Connections for Precise Fitment With All OEM Components

- True Plug-and-Play “Drop-in Fit” Installation Requires Absolutely No Modifications

- Raw Billet Aluminum Finish (#8194)

- Thermal Black Heat Dispersion Powder-Coating Finish (#8194B)

- Made in the USA at PWR North America

- Eliminates Heat Soak and Lowers Intake Air Temperatures (IATs) for Maximum Performance in High-Performance and Race Conditions

- Stage 1 (Stock Tune) +20 WHP / +18 WTQ*

- Stage 2 (With High-Performance Tune) +10 WHP / +20 WTQ*

* Compared to OEM Intercoolers With Same-Day Dyno Testing by VF Engineering

- OEM Part Numbers:

4K0 145 805 P (Left) & 4K0 145 806 B (Right)

⚠️CALIFORNIA WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov