Revo MQB Full Engine Mount Kit | Mk7 | 8V | RV581M500103

More power results in more movement during aggressive acceleration. The stock engine mounts, designed to favor comfort over performance, fail to manage axle hop and torque effectively requiring you to ease off in order to gain traction. Designed to significantly reduce this engine movement, Revo engine mounts use Dual Durometer technology to minimize noise, vibration and harshness levels (NVH) while drastically improving traction and acceleration. The engine, transmission and torque mounts have been CAD designed to offer OE quality fitment with the performance benefits and quality of a Revo product.

Features:

- Dramatically reduce engine movement

- Improved acceleration and torque

- Dual Durometer Technology

- Comes with removal tool for torque mount

Engine & Transmission Mount:

The primary design goal of the engine and transmission mounts was to provide a management system for engine movement during vehicle operation with increased power/torque, in order to retain vehicle acceleration and tire contact during aggressive driving. The aforementioned solution must also continue to dissipate the NVH naturally created by the drivetrain. To accomplish this, the bushing design of past Revo engine mounts was retained in the MQB engine and transmission mounts, allowing Revo engineers to focus their efforts on bushing stiffness/type to accomplish the task.

Torque Mount:

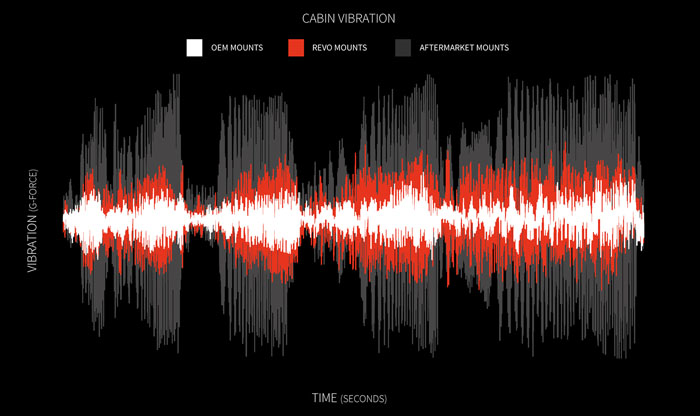

Arguably the most vital engine mount upgrade to consider, testing highlighted that the engines stock lower torque mount allowed a substantial amount of engine movement to occur. Although some improvements were noted during testing of an insert style upgrade designed to stiffen the standard mount, there was a significant increase in NVH felt in the cabin. This was dramatically reduced when completely replaced with the Revo polyurethane torque mount and also improved acceleration.

Materials, Manufacturing, and Equipment:

Effective design and fitment plays a principal role in managing engine movement to ensure optimal acceleration and tire contact with the road while dissipating NVH experienced from the drivetrain. Each component has been designed using CAD technology to ensure precision fitment and is supplied with class 12.9 hardware to replace the standard fixings. To ensure optimum strength and durability, brackets and housings are CNC machined from 6061-billet aluminium and finished with an anodized coating to protect from heat and corrosion.

Includes:

- Torque Mount Tool - RV581M900200

- Torque Mount - RV581M500300

- Transmission Mount - RV581T100100

- Engine Mount - RV581M500102

⚠️CALIFORNIA WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov